The U.S. Department of Labor’s Occupational Safety and Health Administration has imposed a six-figure penalty on a Roslyn-based contractor after a 2020 trench collapse killed two workers.

Superstructure, foundation and concrete company RC Structures Inc. of Roslyn will pay $135,612 in penalties after a 30-foot deep trench in Oyster Bay collapsed, leading to the deaths of Deniz Dos Santos Almeida, 57, and Max Antonio Turcios, 46, both of New Jersey.

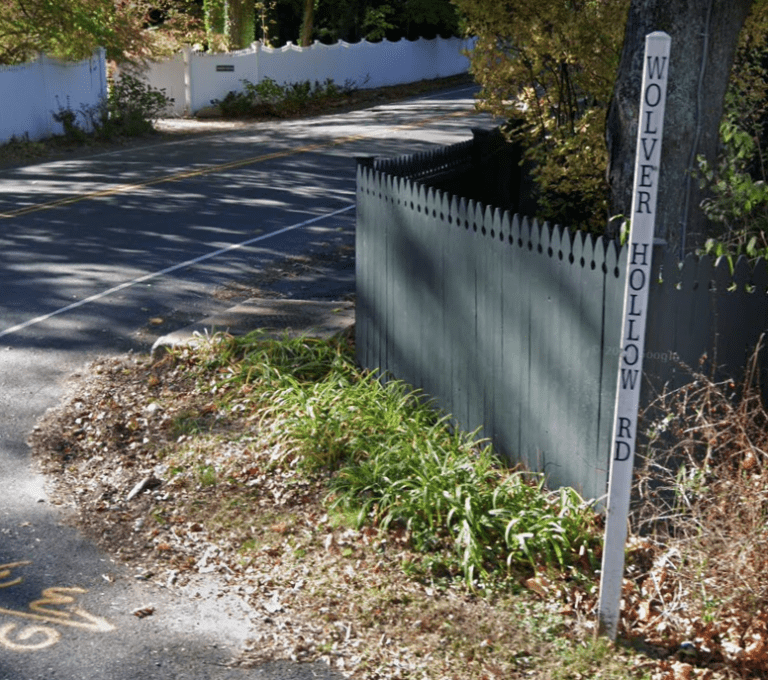

The collapse happened on Jan. 28, 2020, at a site on Wolver Hollow Road, where the company was installing septic rings.

Following a January 2020 investigation, OSHA found that the company did not provide a protective system to prevent a trench collapse and did not remove the employees from the trench after a competent person employed by the company had identified a cave-in hazard. OSHA also found the trench lacked an adequate ladder or other safe means of exit and that the company allowed stacked concrete and excavated materials to be stored at the trench’s edge.

In addition, employees working adjacent to and beneath an operating excavator lacked head protection, exposing them to hazards. OSHA cited RC Structures for willful and serious violations in July, and the company contested its citations to the independent Occupational Safety and Health Review Commission, according to Kevin Sullivan, OSHA Long Island area director.

“A trench can collapse suddenly and with great force, crushing and burying workers in an instant,” Sullivan said. “Amid such dangerous conditions, employers must follow all excavation safety requirements and remove employees to prevent tragedies like this.”

RC Structures agreed to pay the penalties and certify that it will no longer dig excavations. The agreement also commits the company to develop an excavation safety checklist to identify hazards and protective measures for work in excavations; engage a qualified professional safety and health consultant to conduct at least one on-site assessment of excavation safety while employees are performing work in an excavation; and provide company-wide training on ladder safety and hardhat use to its employees.

Efforts to reach the company for comment were unavailing.

OSHA’s Long Island area office conducted the inspection, and trial attorney Molly J. Theobald of the regional office of the solicitor in New York negotiated the settlement agreement.

“No settlement can undo the collapse and its consequences, but it obligates this employer to corrective actions to enhance safe work in excavations and prevent future collapses, injuries and deaths,” regional Solicitor of Labor Jeffrey S. Rogoff said of the case. “The U.S. Department of Labor is committed to enforcing workplace safety laws and achieving settlements designed to prevent hazards from recurring.”

The OSHA shoring requirements are well known, yet contractors continue to make conscious decisions to violate them across the US. Why? The fines, $135,000 in this case, do not provide sufficient incentive to shore the trench excavation because given the total amount of trenching performed each year, and the relatively low (yet predictable) rate of failure makes it cheaper to take the risk and pay the fines than to spend the additional money during construction to provide safe conditions for all trenching activities.

OSHA should revisit the amount of these fines and increase the fines when collapses occur with workers in the trench by a factor off at least 3 and probably more. While the $135,000 fine in this case may seem high, in the big picture it is very small compared to the size of the earth trenching industry in this country.